WORKING WITH TREADWELL

- Our team of engineers are available to support your design requirements by providing technical expertise and specifications.

- Our products are tested and meet relevant compliant codes where required.

- We offer solutions based on practical calculations and data, providing the optimum products for your application.

- We are an established name in New Zealand for providing durable and dependable FRP solutions.

Bespoke & Specialised Projects - Our Process Explained

Enquiry Received

Initial Consultation

An initial consultation is arranged with you and our specialists to qualify your requirements and establish solution options.

Budget Quotation

Treadwell develops and presents a quote.

Quotation Acceptance & Design

Upon acceptance of the quotation, design and engineering commences. Modelling and general assembly drawings are developed.

Final Detailing and Production

This commences upon approval of submitted design.

Shipping and Delivery

Shipping is undertaken upon completion and our team follows through with you to ensure seamless delivery.

What You Get When You Work with Treadwell

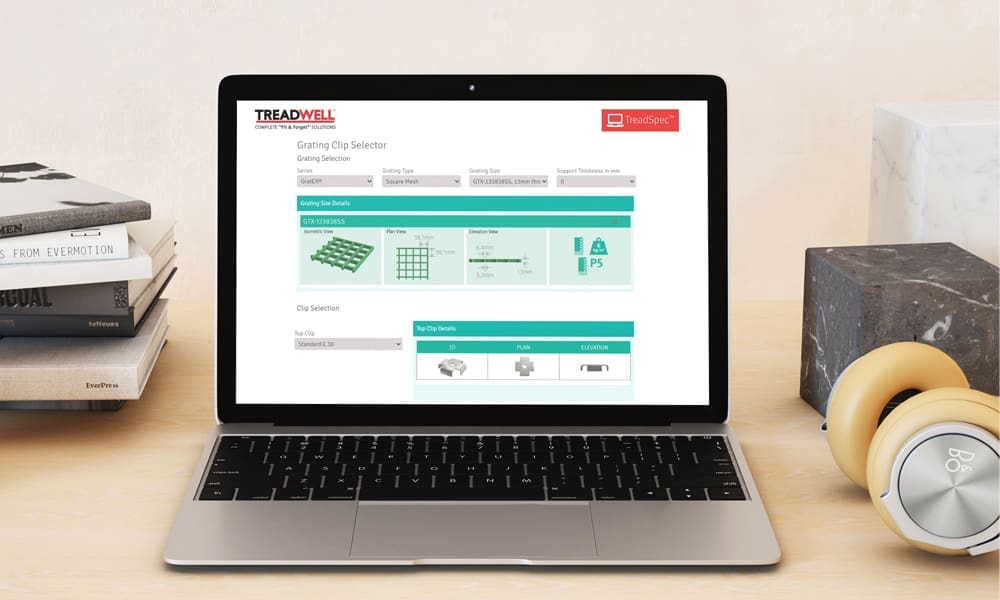

Specialised Online Tools

Our selection tools allow users to fill in selection criteria based on products we carry and will recommend a product suitable to your needs. Our product information has been imprinted on the tool to provide ease of outline and inspiration to architects, engineers, designers and other users. Users can also find all our product files in PDF, DWG, STEP etc. files to download for each of our products. Try our TreadSpec tools here.

Friendly & Professional Design Support

Whether you’re looking to upgrade or completely revamp your rail infrastructure assets, we can help support your design services across all stages of your project lifecycle. Our qualified and experienced engineering team have provided turnkey as well as purely design-based projects. With a knowledgeable team, we are able to provide solutions to fit your requirements.

Cutting Edge Technical Information

Treadwell has a LEAN manufacturing facility, approximately 4000m2 under one roof. Our automated CNC equipment, including state-of-the-art 90,000 PSI waterjet cutting system and beam line ensures minimal material wastage, and as such, eliminates excessive costs. Our internal design engineering department is able to provide design expertise and sign off engineering in all states of Australia (RPEQ and NT certified), and an on-site Quality Assurance team to perform the necessary checks.

With our well-established partnerships with logistics partners across Oceania, complemented by our own fleet of trucks and trailers in Australia, we are able to deliver your projects across the region efficiently and effectively on time and in full.

NZ

NZ

AU

AU

UK

UK