When it comes to designing reliable and efficient cable management systems, the National Electrical Manufacturers Association (NEMA) FG-1 Standard plays an important role, in addition to intrinsic product performance and material composition. This standard outlines key requirements for Fibreglass Reinforced Plastic (FRP) cable trays and ladders, with a focus on structural integrity. Among its critical parameters, loading spans stand out as a factor in the success of any cable tray or ladder installation.

Understanding Loading Spans in NEMA FG-1

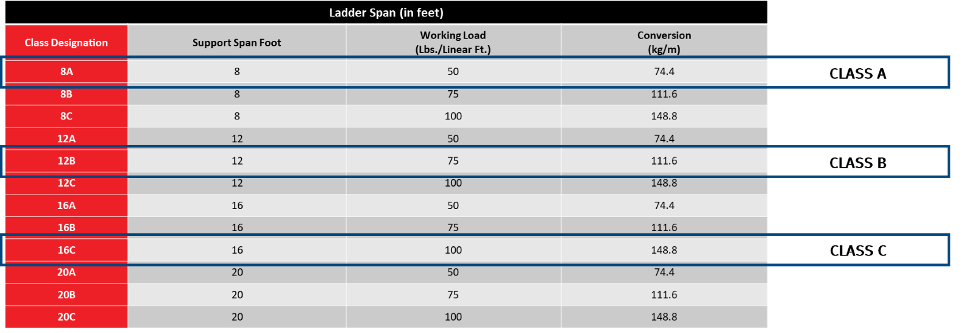

Loading spans refer to the maximum allowable distances between supports that ensure a cable tray or ladder remains stable under specified loads. NEMA FG-1 establishes these spans based on comprehensive testing, simulating industrial applications and various installation conditions to ensure the system’s reliability.

For fibreglass cable trays and ladders, the loading spans cited in NEMA FG-1 reflect the ability to maintain structural integrity under diverse environmental and mechanical stresses. These loading span guidelines also ensure structures are fit for purpose.

Benefits of Loading Spans Compliance

Understanding and complying with the loading spans specified in NEMA FG-1 offers several benefits:

- Tailored Performance for Every Application: By selecting trays or ladders based on their designated class, you ensure that the system can handle the expected load without unnecessary overdesign. This balance is critical for maintaining cost efficiency while guaranteeing performance.

- Confidence in Safety and Compliance: NEMA FG-1 performance standards are the result of rigorous testing. Adhering to them means you’re working with products designed to withstand external stresses, including dynamic loads like vibrations or sudden impacts.

- Fewer Supports, Cleaner Designs: For installations requiring longer spans—up to 6 metres in some cases—fewer supports are needed. This simplifies design layouts, reduces installation time, material and labour costs, and creates a more streamlined final structure.

Here is an additional resource about the NEMA FG-1 Standard – Treadwell Insights NEMA classification

NZ

NZ

AU

AU

UK

UK