Discover the numerous advantages of FRP (Fiber Reinforced Plastic) composites in various industries. From its exceptional strength to its lightweight nature, FRP offers a range of benefits that make it an ideal solution for many applications.

Unmatched Strength of FRP

FRP is known for their unmatched strength, making them an excellent choice for applications that require high durability. FRP has a high strength-to-weight ratio, compared to traditional materials like steel. Based on its application and requirements, Treadwell FRP is constructed with different types of resins and glass fibres to ensure the resultant product is fit for purpose. This makes FRP a versatile material that can be used across a wide range of applications.

Lightweight and Easy to Handle

One of the key advantages of FRP is its lightweight nature. This means that FRP can provide the same level of strength with less weight. This makes FRP easier to handle and transport, reducing the need for heavy machinery and related labour costs for installation.

Corrosion Resistance for Longevity

Treadwell FRP is highly resistant to corrosion, providing a durable and long-lasting solution. Unlike metals, which are prone to corrosion, FRP remain unaffected by moisture, chemicals, and other corrosive substances. This corrosion resistance allows FRP to maintain its strength and integrity even in harsh environments, including marine or chemical processing facilities.

Furthermore, the corrosion resistance of FRP eliminates the need for regular maintenance and repairs, reducing downtime and costs associated with upkeep. This makes FRP a cost-effective choice for industries that require materials with long-term durability.

The image above of balustrades was installed in Henley Beach, South Australia in 2018, photo taken in 2023. The structure maintains corrosion resistance despite being installed in an outdoor coastal environment.

Versatility in Application

FRP materials offer a high level of versatility, making them suitable for a wide range of applications. FRP can be designed into various shapes and sizes, making it adaptable to different design requirements. Treadwell FRP products and solutions have been successfully applied in the food & beverage, marine & shipping, mining & mineral processing, oil & gas, water & wastewater treatment plants, and utilities & rail industries.

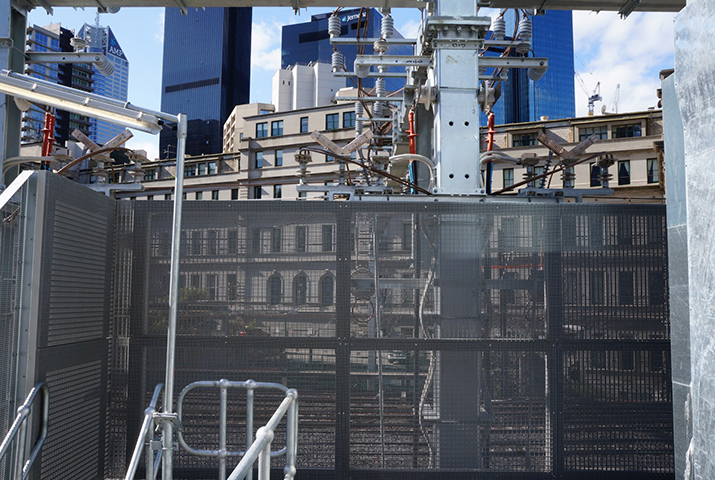

This shows Treadwell FRP micro mesh grating installed as security fencing at a rail station in Victoria, and also for a boardwalk in New South Wales.

Cost-Effective and Low Maintenance

FRP materials offer significant long term savings. While the initial cost of FRP may be higher than traditional materials, the durability and low maintenance requirements of FRP result in reduced lifecycle costs. Unlike metals, which require regular inspections, repairs, and replacements, FRP materials can withstand the test of time with minimal upkeep.

The low maintenance requirements of FRP not only save costs but also reduce downtime and improve operational efficiency. Industries that rely on FRP materials can benefit from increased productivity and reduced maintenance-related disruptions.

In conclusion, the versatility of FRP, combined with its unmatched strength, lightweight nature, corrosion resistance, and cost-effectiveness, makes it a strong and lightweight solution for various industries. Whether it’s in mining, oil & gas, rail, or other applications, FRP offers numerous benefits that contribute to improved performance and longevity.

NZ

NZ

AU

AU

UK

UK