Gold Mine Facility

Gold Mine Facility

With production of around 700,000 ounces of gold each year and a reserve of close to 7 million onces, this gold mine facility sees processing past 2030. Ability for mineral processing to match the capacity to produce such volume often gets diminished over time with structures being eroded.

This brings Treadwell into the fold with products made from fibreglass reinforced plastic (FRP). Treadwell’s EX-Series(R) resin systems can be utilised or tuned to fit the task at hand – to enable a more durable yet structurally sound support to facilitate demand and supply at a more reliable pace.

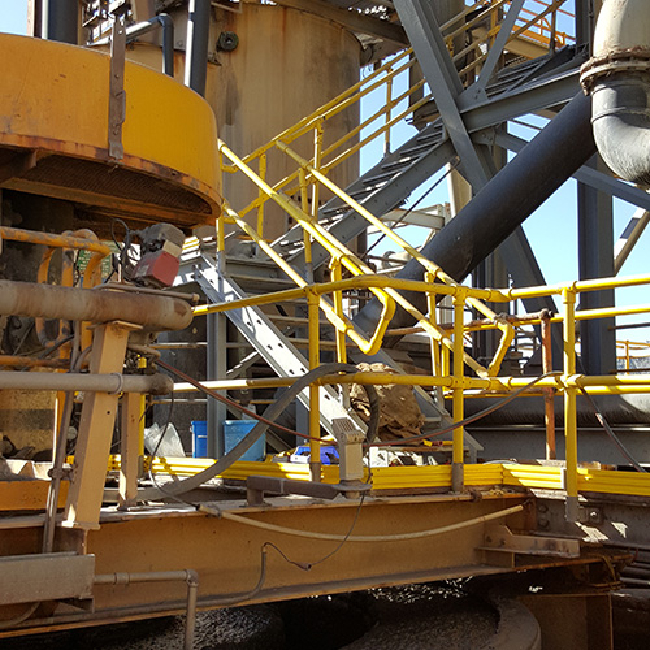

For this support structure, Treadwell provided our GratEX® FRP grating, RailEX® ROUND handrail system as well as ArchitEX™ structural profiles.

Project Challenges

- The old platform/pump support structure had gotten rusted.

- Due to the corrosive nature of process, steel was not a preferred option.

- The site was such that it offered limited crane access so the material of choice ideally had to be one that could be transported without a crane.

- Cost of the project was a critical factor and FRP was cheaper than high coat spec steel.

Project Information

Project Category: Gold mine facility

Scope of Work: Replacement of access and Warman pump support structure in a highly corrosive pump well environment

Treadwell Products :

- GratEX® FRP Grating

- RailEX® ROUND Handrail

- ArchitEX™ Structural Profiles

Total Project Value : $20,000 – FRP could be man handled in

Treadwell Solution

- With Treadwell’s FRP structural systems, grating, structual profiles and handrails, the client was assured of durability and performance as Treadwell’s FRP is virtually immune to all external corrosion and will not rust.

- Lightweight and boasting almost zero maintenance, it was easy to transport the FRP materials without the need of a crane and install on-site.

- Given the nature of FRP, any system utilising it is virtually maintenance free, thus keeping maintenance costs as low as possible.

- FRP is simply fabricated and modified on site. This means there is no need for any hot works permit.

New Zealand

New Zealand

Australia

Australia